Description

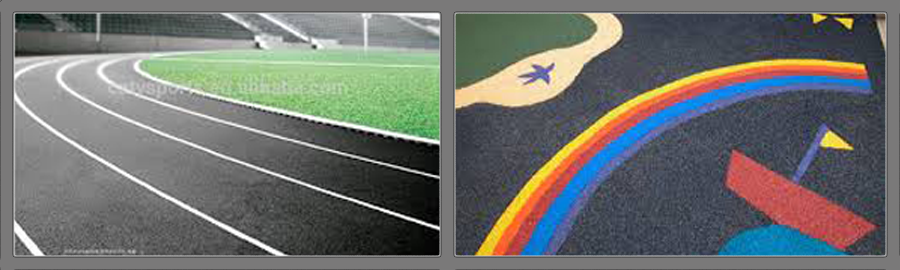

EPDM rubber is used in seals. For example, it is used in cold-room doors since it’s an insulator. It is also used in the face seals of industrial paint spray respirators, where silicon must be avoided. In addition, EPDM is used in glass-run channels, radiators, garden and appliance hoses, tubing, pond liners, washers, belts, electrical insulation, vibrators, O-rings, solar panel heat collectors, UV protection (for tubular motors in shutters) and speaker cone surrounds. It is also used as a medium for water resistance in electrical cable-jointing, roofing membranes (since it does not pollute the run-off rainwater, which is of vital importance for rainwater harvesting), geomembranes, rubber mechanical goods, plastic impact modification, thermoplastic, vulcanizates, and many other applications. It is even used in golf club grips. It is applied to concrete, asphalt, screenings, interlocking brick, wood etc. to create a non-slip, soft, porous safety surface for wet-deck areas such as pool decks or playgrounds. Other uses are where water pumps, thermostats, EGR valves, EGR coolers, heaters, oil coolers, radiators and degas bottles are connected with EPDM hoses; as well as charge air tubing on turbo charged engines to connect the cold side of the charge air cooler (inter cooler) to the intake manifold.

EPDMbond is unique because it will now let you recolor EPDM rubber surfaces where it was not possible before.

Features:

• Non toxic

• Chemically bonds to EPDM rubber surfaces

• UV stable

• Abrasion resistant

• Very flexible and bends along with substrate without cracking or peeling.

• Maintains the non slip surface characteristics of the EPDM substrate.

• Very durable.

Note: Especially developed for coloring EPDM surfaces and may not work on only all rubber surfaces.

We can mix and match almost any color you need. Special color matching is available in quarts, gallons, 5 gallon pails and 50 gallon drums. If the color you want is not on the RAL color chart you can send us a sample of the color and we will match it for you.

Please specify your desired RAL color number in the Comment/Delivery section when you check out or indicate if you are sending a sample.

Below are our 14 Standard colours

FULL RAL colour chart

Application instructions for EPDM Paint

1) Clean surface well with Parakleen or lacquer thinner to remove grease, grime, oils or other contaminants from the surface.

2) Allow surface to dry before spraying, and mask areas not to be sprayed.

3) Stir can of paint well to make sure it is completely mixed before putting it in the spray equipment. If using a paint brush, make sure brush is clean.

4) Set spray gun to a pressure of 30 to 40 psi. Clean spray equipment with ordinary gun cleaner after use.

5) Before applying on entire surface test on a small area first.

6) Spray from about 4 to 6 inches away in slow even strokes. Apply 1 to 2 coats depending on coverage needed. If using a brush, apply in light even coats.

7) If you wish to heat dry the surface you sprayed you can set the heat gun at 350F and blow over the area that was colored with EPDMbond for about 45 seconds to 1 minute and then let air dry for about 10 minutes before handling parts or touching surface. If using oven to cure the paint leave recently colored part in oven at 350F for about 45 seconds to 1 minute to cure.

Coming Soon

Coming Soon